01

02

5-8°C Cooling Improvement

03

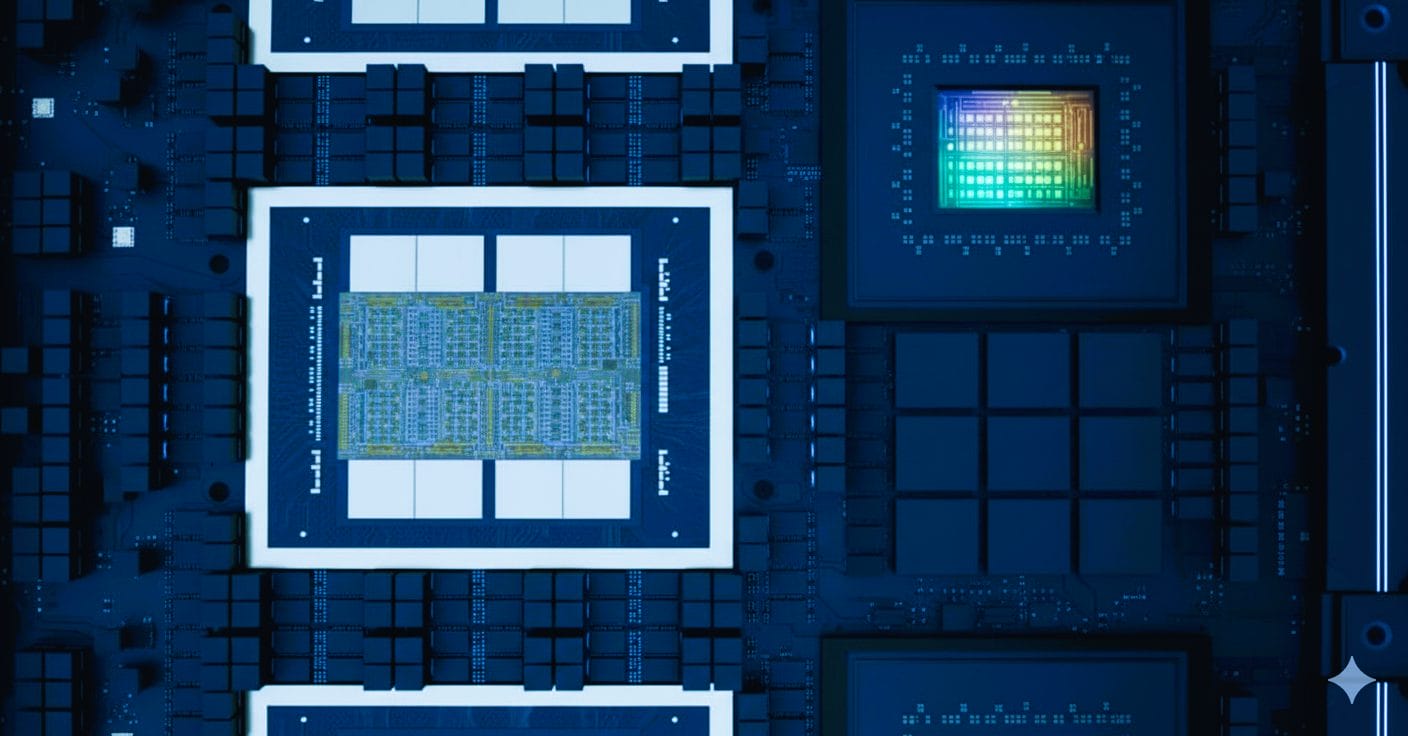

Engineered for Kilowatt-scale Devices

5-8°C cooling benefit

on 1,000W+ devices

Boston Materials delivers improved cooling for kilowatt-scale devices, validated on previous-generation NVIDIA data center GPUs and test vehicles replicating Blackwell.

Data Center

Operators

A 5 to 8°C device-level cooling improvement enables more competitive application software performance and value, and the ability to deliver at greater energy efficiency.

Rack-Scale

Integrators

A 5 to 8°C device-level cooling improvement lowers energy consumption, reducing operational costs and improving Power Usage Effectiveness (PUE).

Thermal & Silicon

Designers

A 5 to 8°C device-level cooling improvement increases processor power and performance envelopes, while enabling simpler server and liquid cooling designs.

Unlock a New

Thermal Advantage

A New Class of Thermal InterfaceTM

Z-axis Carbon Fiber + Liquid Metal Composite, Exclusively from Boston Materials