Purpose-built for high power devices with large die array warpage

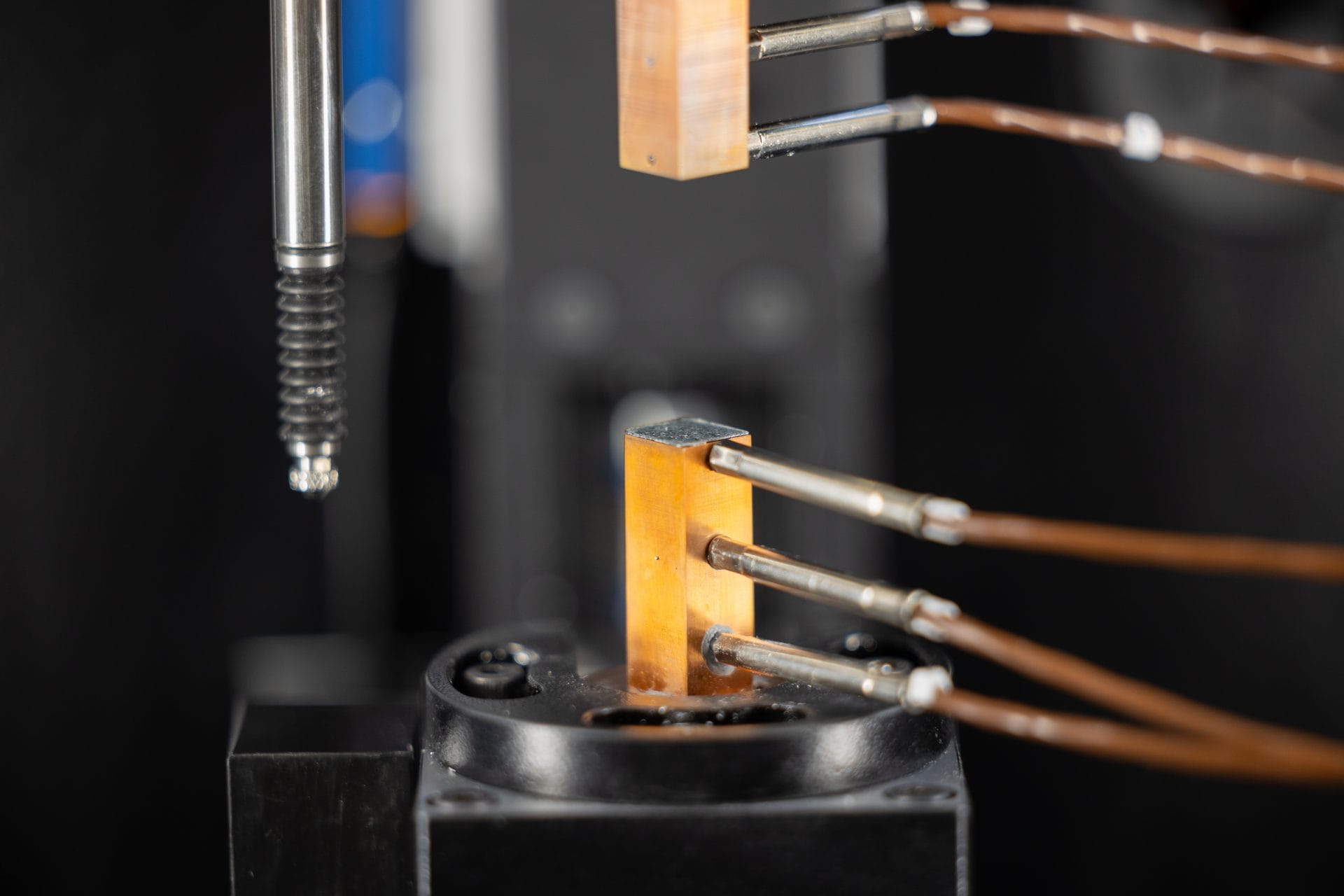

5 mm2-K/W thermal resistance at 150µm bond line thickness

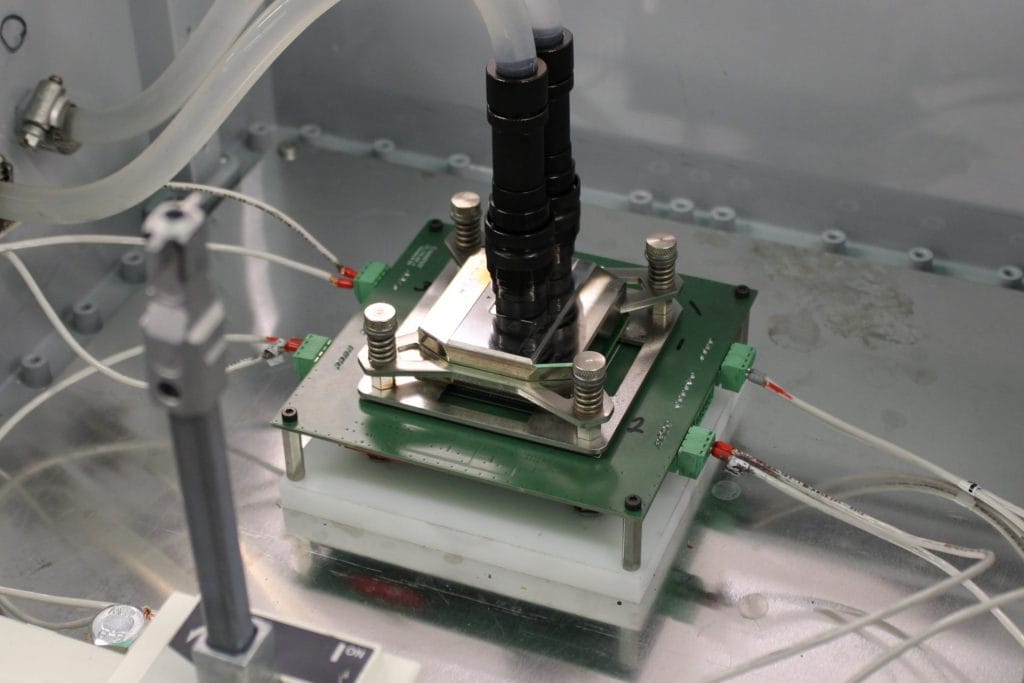

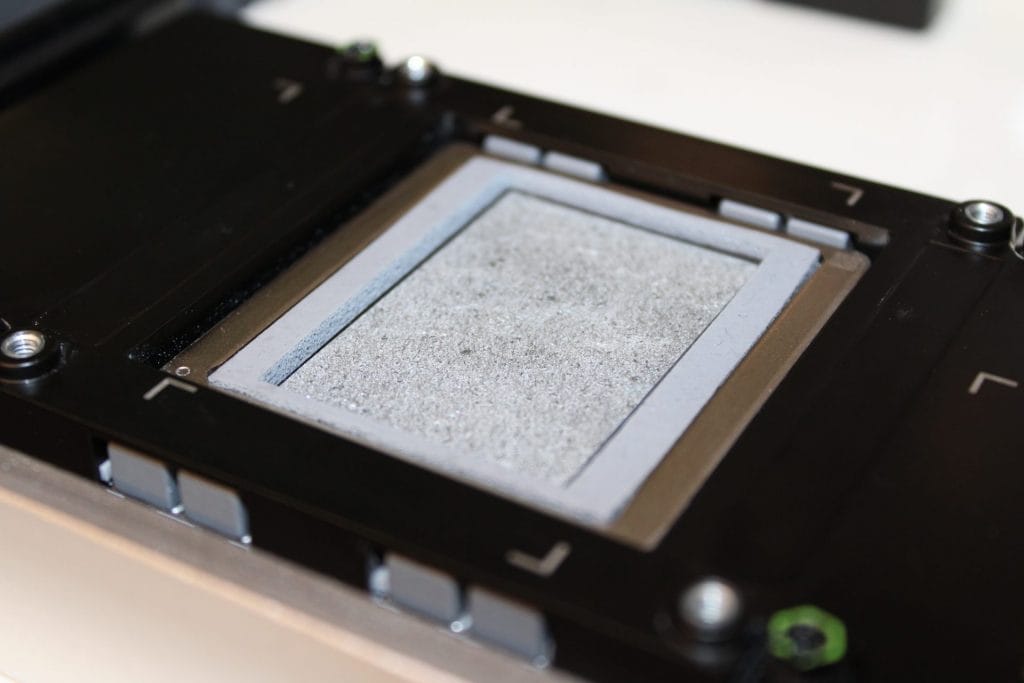

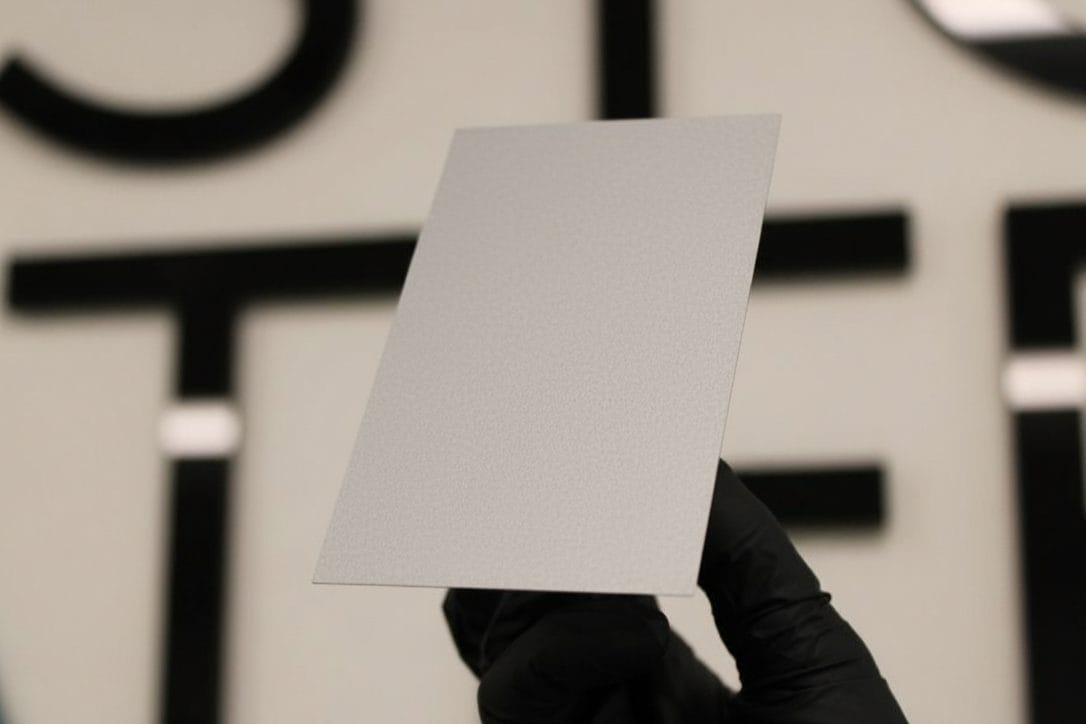

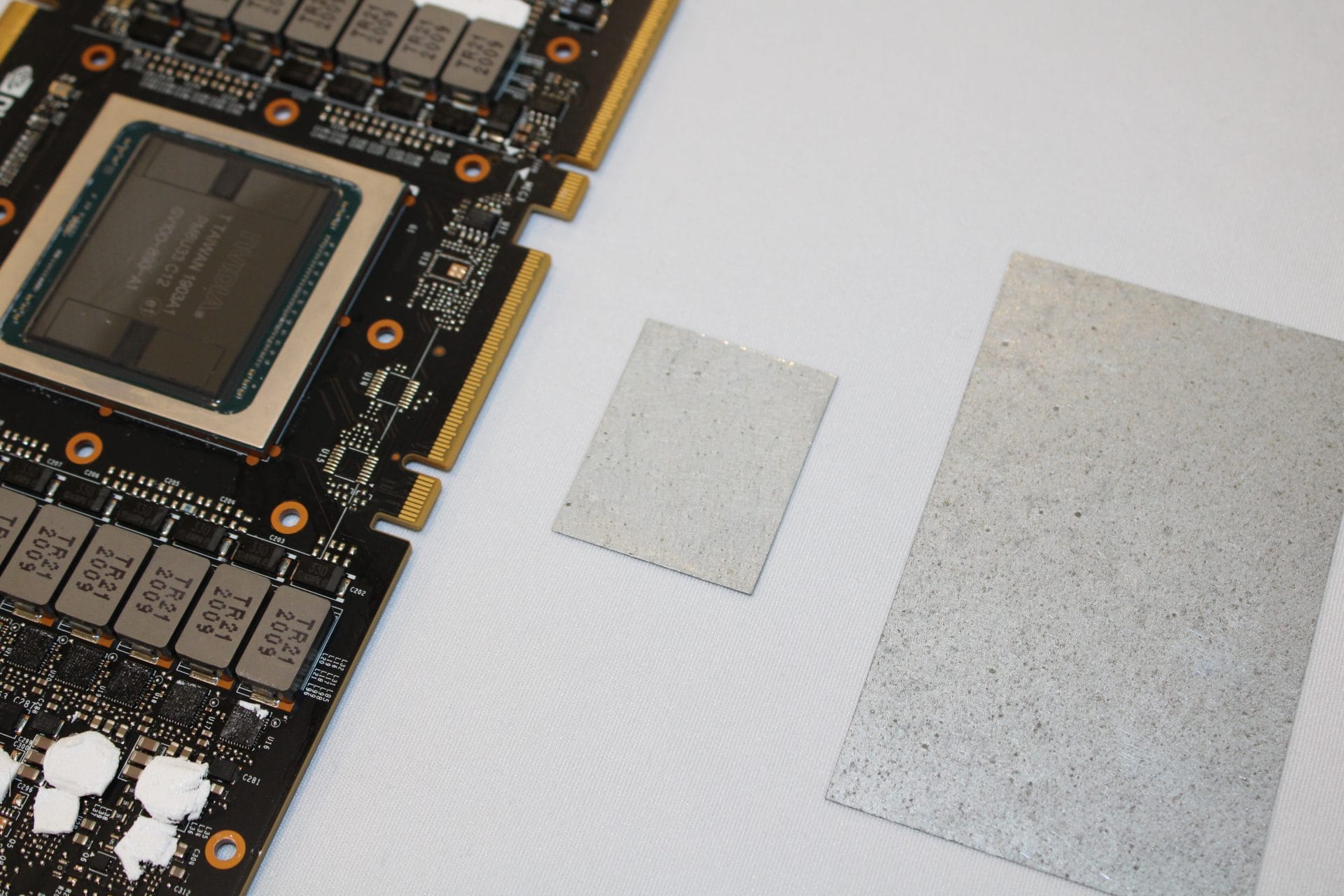

Pick-and-placeable preform drops into automated assembly lines

Liquid metal is retained by carbon fiber, remains solid during assembly

Turnkey integration without any changes to silicon

No backside metallization or surface treatment is needed on the silicon

Drastic cooling impact to HBM, I/O, and CPO

Best performance when heat generation continues out to the edge of die array

Ready for wafer-scale compute

Max preform size of 150x150mm, roadmap to 240x240mm

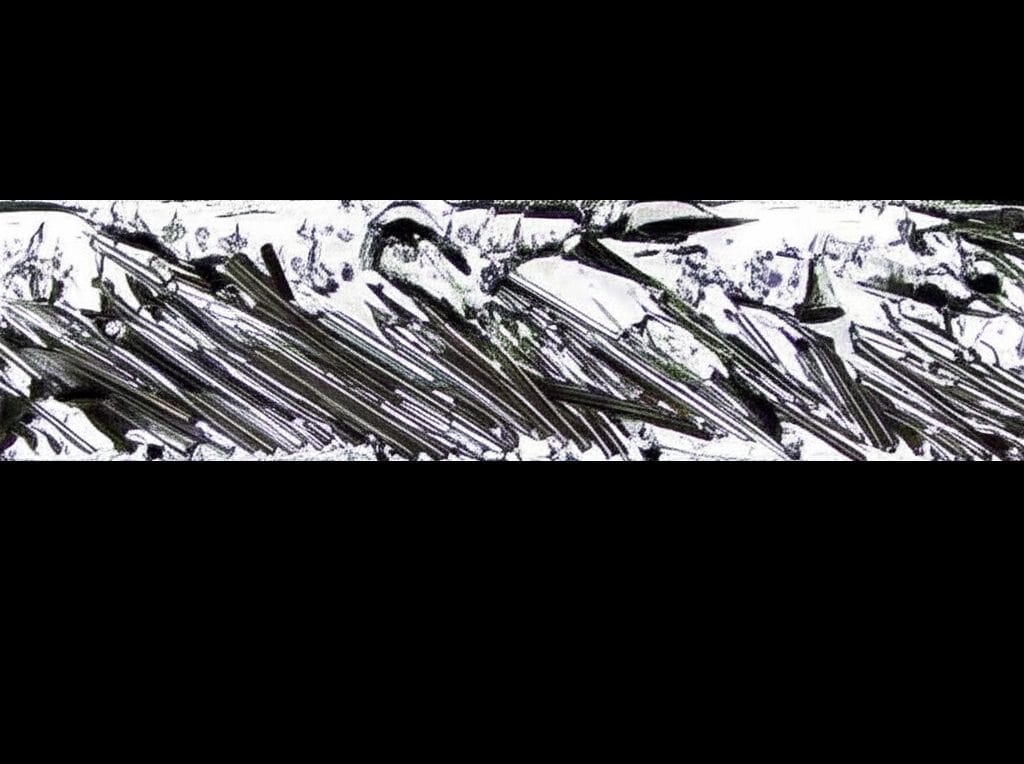

Carbon fibers with 900 W/m-K thermal conductivity are vertically aligned using Boston Materials’ patented Z-axis Fiber™ technology and embedded within a liquid metal matrix (gallium-based).

The Z-axis aligned carbon fibers create a scaffold that retains the liquid metal into a preform that is solid during assembly. The preform melts during device operation but the liquid metal is still retained by the carbon fiber, ensuring a stable bond line thickness.

Liquid Metal ZRT® is optimized for TIM1.5 applications in advanced microprocessors where very low thermal resistance, containment of the liquid metal, repeatable surface coverage, and high reliability are critical.

This product does not contain nanomaterials.

Request ZRT® Liquid Metal Film TIM Data Sheet

A New Class of Thermal InterfaceTM

Enhance Liquid Cooling

with Liquid Metal ZRT®

Liquid Cooling for Kilowatt-scale Devices

- 5°C+ cooling improvement compared to traditional thermal grease in high power applications

- Offering secondary benefits in terms of water savings and reduced leakage

- Validated on direct-to-chip liquid cooled 1,000W thermal test vehicle (TTV)